By CAMERON VREDEVELD

Capital News Service

LANSING — The Great Lakes basin supplies breweries with some of the freshest water in the country.

But if brewers like what they taste, some experts suggest they make some changes in how they use that water.

“You can’t brew great beer without great water,” said Dave Engbers, co-founder of Founders Brewing Co. in Grand Rapids.

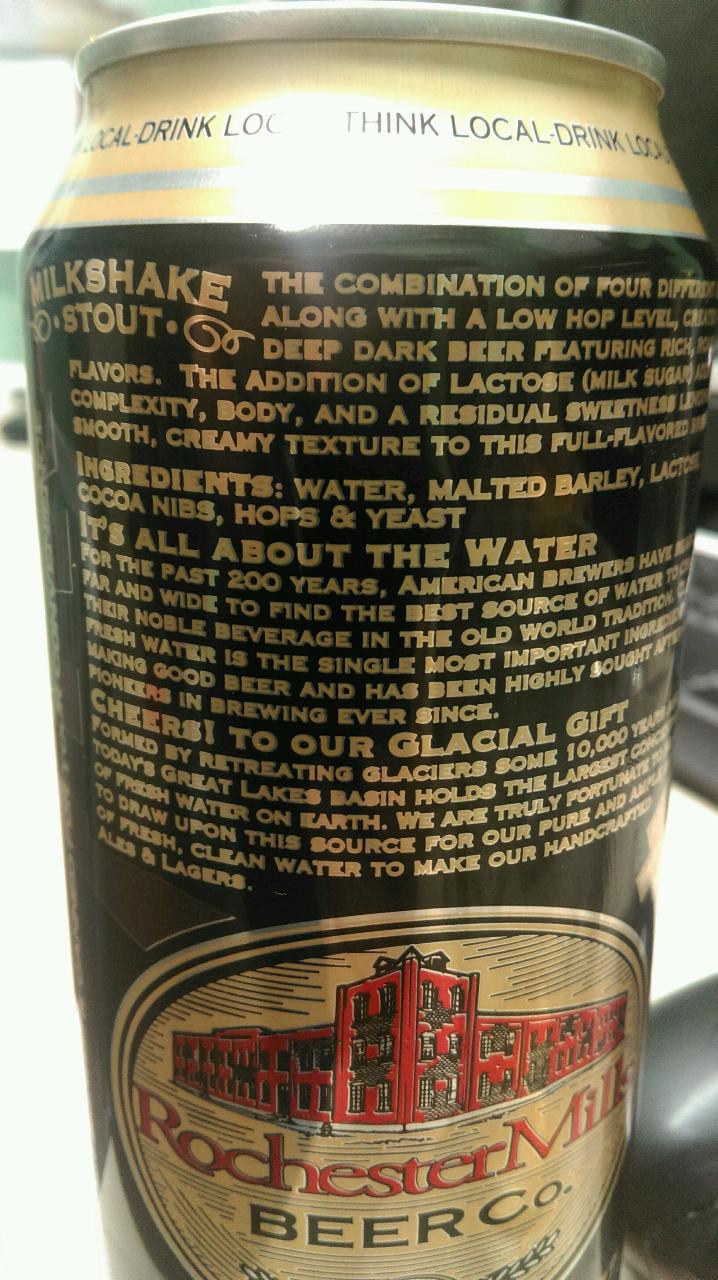

Rochester Mills Brewery in Rochester celebrates the region’s “glacial gift” of water on its beer label. Credit: Ben Poulson.

Engbers was a featured speaker at a recent Great Lakes Water Conservation Conference in Grand Rapids. Beer scientists, crafters and experts from as far as Alaska gathered for a three-day conference to discuss water sustainability.

“Sustaining water quality and getting the most out of the water, that’s what is most important,” said Lucy Saunders, the event organizer and Wisconsin author of “Cooking with Beer.”

Saunders, who has taught at the Siebel Institute Brewing Studies Program in Chicago, said breweries typically use between seven and 12 gallons of water to produce one gallon of beer.

“Brewers are trying now to use more along the lines of three gallons of water to every one gallon of beer,” said Saunders.

BarFly Ventures is the parent company of HopCat—a Grand Rapids-based bar chain— and of the Grand Rapids Brewing.

“Both of our breweries are powered by steam energy, and we recycle all of the water used to cool our beer before it is transferred into fermenters,” said Autumn Sands, the sustainability coordinator for BarFly. “We also use the excess water from the process to clean our tanks, after they are emptied with each batch.”

Sands said that while each batch varies, Grand Rapids Brewing averages about five gallons of water to brew one gallon of beer.

Some companies are addressing water use beyond their own operations. For example, BarFly started the “No Fracking Way” campaign to raise public opposition to underground drilling with hydraulic pumps.

Serving as a method to drill for oil and natural gas, hydraulic fracturing uses vast amounts of pressurized water. Sands said that water used during each “frack” is 100-percent consumptive, meaning it is so contaminated that it should never be returned to the water cycle.

The Great Lakes hold a gold mine of brewing potential—with 95 percent of the nation’s fresh water supply. And more than 95 percent of beer—from process to production—is water, said Sands.

That means brewers must emphasize reuse.

“We have a responsibility to ourselves and to our communities to be environmentally aware and to promote responsible business practices,” said Sands. “Massive water withdrawals and irreversible contamination would be a death blow to the brewing industry and the Great Lakes’ economy.”

BarFly’s fracking campaign has gathered momentum through conferences and special events like one held at HopCat’s East Lansing bar last spring.

“At the end of the day, breweries need to see water as an investment,” said Saunders. “There is a cost-versus-value aspect, and they need to realize that water can be reused during the brewing process before being returned to the water table.”

Saunders stressed the importance of breweries uniting for a common purpose.

“It is important that we have collaboration, especially on an issue like this. Water is a vital natural resource in the brewing process, and we need to work together to be smart about using it.”

Cameron Vredeveld writes for Great Lakes Echo.